LETTERS of ARA

An online journal & newsletter, exploring areas of influence & interest for Ara the altar.

Behind the altar | Vol. 5 Sand Casting

A documented journey of my first sand casting project

WHAT IS SAND CASTING?

Sand casting is an ancient technique used to cast molten metal into a desired form.

A special kind of compressed sand is used to create a mould containing a cavity into which molten metal is poured.

SAND CASTING

A RESPONSIBLE APPROACH

Unlike lost wax casting, the majority of the material (sand) used to create the mould can be used time and time again, making it a renewable and much more sustainable process, producing minimal waste.

Introducing sand casting into the Ara workshop enables me to cast certain pieces in house. This means less transport of waxes and castings to and from the casting house, minimising CO2 output.

Taking it one step further, rather than using a powerful gas torch to melt the metal for this process, I have invested in an electric furnace. The metal can be melted using the workshop’s electricity, powered by 100% renewable energy. After doing a lot if research I chose a furnace made here in the UK, again, lessening CO2 output.

A ONE-OFF PROCESS

Unlike the silicone or rubber moulds used in combination with lost-wax casting —from which wax forms can be produced over and over again— sandcasting requires a new mould to be made for every cast.

Sand casting therefore lends itself to the creation of more organic, unique works.

SURFACE TEXTURE

Depending on how compressed the sand is during the pour of the molten metal, the work can adopt a sand-like, less refined surface texture, which adds to the organic nature of this process.

The completed project — the cast recycled silver pebble pendant alongside the original

THE PROJECT

“Lauren was so enthusiastic, accommodating and thoughtful throughout the entire process, and I felt very included in the decision making right from the very start.

The pendant turned out even better than I could have ever imagined!

And I would recommend Lauren, and the magic she creates in her studio, every day of the week.”

A CAST RECYCLED SILVER PEBBLE PENDANT

A very dear client approached me to explore potential projects to create a gift for her beloved mum’s 60th birthday.

We decided on the perfect project — a pebble found on her mum’s favourite beach, one that spoke to my client and that would suit the recipient's style.

This nature of this piece meant that it was such a special project for my first attempt at sand casting.

Below I outline the process I took in the creation of this project, and the learning along the way.

Refining the sand with a wood handled taping knife

THE PROCESS

I. PREPPING THE SAND

A successful cast hinges largely on the successful construction of the mould.

This is a slow process that requires a lot of care and attention to detail.

The first step is to refine the texture of the sand and remove any lumps or bumps so when it’s compressed into the mould, it can be packed down as densely as possible.

I used a taping knife to repeatedly chop up the sand. A metal ruler can be used for this but I found the wooden handle of the taping knife a more ergonomic tool for my hyper-mobile joints.

II. FILLING THE MOULD

Once I was happy the sand was a finer texture, I began to pack it tightly into one half of the mould.

I alternated adding some sand with hammering it down with a weighty hammer to make it more compact and dense.

Once the mould was full, I used the taping knife to scrape the excess sand off the top and flip it over, revealing a smooth and compact surface.

As you will see in the second image, my first attempt wasn’t as compact as it could be so I removed the sand and redid the process with a little more elbow grease so I was happy the sand was nice and snug (see below images).

III. POSITIONING THE OBJECT

I pressed the pebble into the sand so it sat about half way in, pressing down evenly from either side of a ruler.

Once the pebble was in position, using a dry paintbrush I carefully brushed a little talc over the sand to stop it from sticking to the sand that would fill the other half of the mould.

I precisely connected the other half of the mould, being careful to make sure the line engraved on both sides met neatly as this is crucial to ensuring the shape of the final cast is not distorted.

I then packed the empty top half of the mould with more sand, this time being careful not to dislodge the pebble with the pressure of the hammering.

After scraping off the excess sand from the top of the mould, I carefully pulled apart the two ends and removed the pebble to reveal a cavity within either side of the mould.

A first successful cast

IV. CARVING FOR THE SPRUE AND AIRVENTS

This is the most complex part of the process, first carving a well for the molten metal to pour into the widest part of the pebble shape. It’s really important at this point to make the hole wide enough so that the metal will flow as quickly as possible into the mould before it starts to cool — whilst also avoiding impacting on the shape of the cavity.

Secondly, the air that is trapped inside the cavity needs to go somewhere when the molten metal is poured in, otherwise air bubbles will be formed and the cast will not be successful.

For this, I pushed 6 holes around the edge of the mould to create 6 air vents. I then carved a tiny channel from the pebble cavity to each of the holes to provide a release for any trapped air. Here I had to be careful to brush out any sand that fell into the vents to maintain a clear airway.

Once I was happy with all of the carving within the mould and that the pebble shape remained in tact, I rejoined the two parts of the mould, ready for casting.

My electric furnace — made in the UK

The aftermath

V. THE CAST

Rather than using gas to melt the metal, I used an electric furness - powered by my workshop’s electricity which uses 100% renewable energy.

I measured out enough silver to ensure there would be enough weight and volume of molten metal to move with greater force into the mould when poured - to completely fill the mould and create a sprue (excess metal from the pour).

I placed the silver into a crucible and set the furnace to rise to the correct melting temperature. The temperature I brought the metal to was actually higher than the metal melting point as the moment the crucible moves away from the furnace it begins to cool. It’s really important to ensure that the metal is still fully molten when it pours into the mould.

After a swift and direct pour (heat gloves on!), once the metal had stopped smoking I opened up the mould to check if it had been a successful cast.

I was over the moon with my first attempt - a good clean cast with minimal draw into the air vents.

The cast pebble with sprue (where the metal poured into the mould)

VI. THE CLEAN UP

Once the silver pebble had fully cooled, I hand pierced (sawed) off the sprue (the excess metal from the pour).

I sanded down any excess from the air vents.

Where the molten metal made contact with the sand, the sand burned and went black. As this cannot be used again, I carefully separated it from the rest of the sand, which can be used again and again.

Once I was happy with the shape of the pebble, I took it through various stages of sanding and I actually gave the pebble a polish so I could check in wiht my client to ensure she was happy to proceed with this first cast.

The surface took on a few little markings from the casting process which we agreed work well with the overall aesthetic of the piece.

VII. CREATE AND ATTACH THE BALE

The next step was to work out the design of bale, to suit the pebble and the wearer.

We decided on a fairly thick wire for the bale in an organic oval shape to suit the form of the pebble, without drawing focus away from it.

Once I had made the bale, I worked out the positioning — with gravity in mind, based on how the shape would hang against the body.

VIII. FINISHING AND POLISHING

After soldering the bale on, the final steps were to sand off any excess solder and polish up the pendant to a high lustre.

I sent the pendant to be hallmarked at my closest Assay Office in Sheffield.

The pendant now bears my makers mark and the the letter X, depicting the year in which it was made — a lovely touch for my client’s mum who celebrated her birthday this year.

Read more about the hallmarking components here.

Finally, I added the pendant to its chain that we chose again to suit the weight and form of the pendant.

I am over the moon with my first sand casting project and can’t wait to develop this practice further.

If you’d like to work together to create something unique using this method, please get in touch.

L x

Behind the altar | Vol. 4 Hallmarking

A closer look at hallmarking and Ara’s considerations to make this a sustainable practice

WHAT IS HALLMARKING?

Hallmarking is the oldest form of consumer protection.

Here in the UK, when selling a piece of jewellery (or, ‘article’), if describing the content of the metal as silver, gold, platinum or palladium, there is a legal requirement to ensure the article has been hallmarked to reflect the description.

UK hallmarking can only be undertaken by one of the UK’s four Assay Offices — London, Birmingham, Edinburgh or Sheffield.

Hallmarking follows an independent assessment of quality and content, the process of which is to 'assay' — meaning to test and assess the precious metal content of an item.

WHY ARen’t all ARA PIECEs HALLMARKED?

The legal requirement to hallmark an article only applies to those over a certain weight, depending on the metal content —

Silver | 7.78 grams

Gold | 1.0 gram

Platinum | 0.5 grams

Palladium | 1.0 gram

Keeping certain pieces within these weights means they are exempt from the legal requirement for hallmarking, which in turn means they have a shorter turnaround time and will not incur the additional costs associated with hallmarking.

A SUSTAINABLE APPROACH TO HALLMARKING

MINIMISING CARBON FOOTPRINT

To minimise carbon footprint, I choose to send my articles to my closest Assay Office — the Sheffield Assay Office.

I have a unique mark registered at the Sheffield Assay Office which can be used to mark only pieces made by me. This mark is always accompanied by the distinctive Yorkshire rose as the Sheffield ‘Town’ mark (see more in ‘The Marks’).

LASER MARKING

The traditional mark is hand struck with a heavy metal punch.

As my pieces vary greatly in size and shape, several different punches would require creating to accommodate the different designs.

Instead, I opted to use a laser engraved mark. This is an electronic process and it means that the shape and size of the hallmark can be easily amended each time to suit the form of the particular article, resulting in less energy than would be required to produce multiple physical punches.

THE MARKS

You will always see at least three marks — the sponsor's (or maker’s) mark, the fineness mark and the assay office mark are all compulsory.

I. THE SPONSOR OR MAKER’S MARK

The first of three compulsory marks —

The sponsor or maker’s mark is unique to the Assay Office or to the individual maker or company; no two marks are the same.

This mark must feature at least two letters within a surround. The symbol I chose was the one I felt most closely resembled an altar or place for an offering.

The black is where metal will be removed, leaving the white raised comparatively.

II. METAL AND FINENESS (PURITY) MARK

The second compulsory mark —

This mark indicates the precious metal content of the article.

The fineness is indicated by a millesimal number (parts per thousand) and the metal type is indicated by the shape of the surround.

III. ASSAY OFFICE MARK

The final compulsory mark —

This mark indicates the particular Assay Office at which the article was tested and marked.

All Ara pieces bear the Yorkshire Rose — the mark of my closest Assay Office in Sheffield.

IV. TRADITIONAL FINENESS SYMBOLS

An optional mark —

Including the lion passant for 925 silver, the Britannia mark for 958 silver, the crown for gold, and the orb for 950 platinum.

V. THE DATE LETTER

Another optional mark —

Until 1999 the date letter was compulsory.

This is no longer the case, but it can be applied voluntarily in addition to the compulsory marks. The date letter changes once a year on January 1st.

AN EXAMPLE

From this example you can see that the article —

i) was made by me

ii) was made from no less than 925 sterling silver

iii) was marked at the Sheffield Assay Office in the year 2020

I hope you enjoyed a closer look at hallmarking.

If there’s ever anything you’d like me to explore as part of ‘Behind the altar’ please let me know.

Lx

Behind the altar | Vol. 3 NATURAL DYEING WITH EUCALYPTUS

How to dye natural fabric with eucalyptus leaves — a step by step guide

Ara’s European hemp pockets — naturally dyed with eucalyptus leaves

VOL. 3 —

NATURAL DYEING WITH EUCALYPTUS

For this month’s volume of Behind the altar, I thought I’d share the process I’ve just been through to dye Ara’s next batch of hemp pockets.

Every piece of Ara adornment is accompanied by a european hemp pocket, designed in house and ethically made here in the UK with minimal waste.

For each new batch of bags, I naturally dye the fabric by hand, using botanical or food waste dye.

David was due to prune a eucalyptus tree so I thought I’d put the leaves to use for my next batch of hand dyeing, rather than letting it go to waste.

Freshly pruned UK grown eucalyptus leaves

PREP THE FABRIC

For natural dyeing, there are several steps to prep the fabric:

Scour the fabric —

I washed it on a cool wash with PH neutral washing powder. This step is to remove any residue on the fabric that could impact the dyeing process

Soy milk binder —

When using plant based fibres, the colour can bind better to the fabric if treated first with soy milk.

Lyra and Atlas have a helpful guide to pre-treating your fabric with soy milk here

This is a fairly slow process so worth doing around a week in advance for the full benefit.

Soak —

Once ready to prepare the dye, I popped the fabric in water to soak which allows any creases to lessen before I placed it into the dye bath.

The pre-treated hemp fabric soaking in water

2. CREATE THE DYE BATH

I separated the eucalyptus leaves from their stems (in hindsight I may have gotten some good colour for the stems so I will try including those next time). I tore up the leaves exposing more of the inside of the leaf, to help extract as much of the colour as possible.

The pot

NB — I use a large aluminium pot for my dye baths. Some dyers advise using a stainless steel pot as this will not result in a reaction from the dye to the aluminium. An aluminium pot could be another factor that would impact on the colour the dye takes.

I filled up my pot of leaves with water and brought it to the boil before quickly reducing the heat to a simmer.

From here I kept returning to the pot every so often to see how the colour was developing. Once it had reached a bold enough colour I took the pan off the heat and removed the leaves with a sieve.

The eucalyptus leaves after the dye has been extracted

3. DYEING THE FABRIC

I added one piece of water soaked fabric to the dye bath at a time to make sure the fabric had room to move around within the pot.

I returned to pot to stir the fabric regularly so the dye wouldn’t sit for too long in any creases.

The fabric is ready to remove as soon as you’re satisfied with the colour but leaving it overnight gives time for a deeper colour to develop on the fabric.

Stirring the hemp fabric in the dye bath

4. POST DYE

Once out of the pot, I washed the fabric with ph neutral washing powder once again.

I hung the fabric to air dry. This time I made the mistake of leaving some of my fabric to dry outside on a sunny day. When I brought it in once dry I noticed that one side of the fabric was lighter than the other! So the advice to avoid natural dye from dyeing in sunlight is best taken!

Interestingly I got several different shades of dye from the one dye bath, ranging from a soft sand colour, to earthy terracotta

Different shades of the air dried eucalyptus dyed hemp fabric

THE FINISHED BAGS

I gently steamed each piece of fabric to ease any creases from the wash and to try and get a smoother surface in preparation for sewing.

I sent the fabric to the talented UK based maker who cuts and sews the dyed hemp fabric into Ara’s uniquely designed pockets, to keep Ara adornment safe.

The pockets are carefully sewn with GOTS certified organic cotton thread. The very little waste that is produced from the edges of the fabric is returned to me to be repurposed.

A finished hemp pocket

I hope you enjoyed this insight into the process of natural dyeing with eucalyptus leaves.

I have a list of topics growing for subjects to explore as part of Behind the altar — if there’s anything you’re curious for me to explore, just let me know.

L x

Behind the altar | Vol. 2 Making the Braided Grass Ring

Volume 2 of Behind the altar explores the creation of Ritual Object III - The Braided Grass Ring

VOL. 2 —

MAKING THE BRAIDED GRASS RING

Before launching Behind the altar I did an open call to invite suggestions of topics for me to explore as part of this project.

Something that many of you were interested to know more about was the journey a piece of Ara adornment takes from start to finish.

For volume 2, I thought I’d walk you through the creation of the Braided Grass Ring.

THE CONCEPT

—

The idea for the Objects of Ritual family was inspired by a handful of props I used to accompany my recycled gold Phase Fine shoot.

I decided to create a mini collection capturing three objects as wearable sculptures — a collection of protective amulets; miniature sculptures to adorn the body.

One of which was the braided grass ring.

CREATING THE ORIGINAL BRAID

—

As this was a sculptural series, working with wax to sculpt and create the objects —to later be cast in recycled solid gold and silver— was the natural fit.

I toyed with the idea of carving the braided grass ring in wax too but I wanted the grass to look as authentic as possible, with the natural imperfections of actual grass.

Instead, I foraged some long grass growing locally and knotted it at one end before braiding the length fairly tightly to get an even braid.

The resulting braid was delicate and hollow with some small gaps — features which would not lend themselves well to the mould making process in which an object is surrounded with melted rubber. The braid would not have withstood the weight of the rubber, and the rubber would also have seeped into the gaps.

In attempt to make the braid more suitable for mould making, I let the braid air dry over several weeks before stretching the length out on my weaving loom and securing it with paper tape.

I gently painted the surface of the braid with melted candle wax, sealing any gaps and making a stronger form to withstand the mould making process. I kept the wax as thin as possible, to retain some of the natural surface texture of the grass.

CREATING THE WAX

—

As moulds have a size limit, I carefully cut the braid into three. Each unique in its own form, and long enough to make a ring band. I handed them over to my casting house to have a mould made of each - at that point we were unsure how each of them would translate once cast.

With a successful mould of each, the next step was to inject the mould with wax.

For this step, I measured out and formed the wax into a band shape, to size, and melted each end of the braid together using the flame of my oil burner.

Working away any excess way and smoothing the join so it blends in as much as possible.

LOST WAX CASTING

—

Once happy with the wax, I sent it to my casting house who attach many waxes to a ‘tree’, to cast a full batch in recycled solid 925 sterling silver or recycled 9ct gold.

Over time, once I have made a ring in a particular size, I have a new mould made of the silver ring (which is ideal for mould making), so that future orders in that size can be cast directly by my casting house, without having to send the wax to me to shape into a band. This streamlines the process and helps to minimise carbon footprint.

REFINING AND RESIZING

—

The silver or gold cast band is returned to me with a sprue still attached (where the metal flowed down the tree into the wax ring).

I saw off the sprue, file down any excess metal and then go through a phase of sanding to prepare it for polishing.

I also reshape and resize the ring at this point as the metal shrinks a couple of percent during the casting process.

POLISHING

—

Only once the ring has been through every stage of sanding and buffing, I pop it into my polishing tumbler —more fondly known as ‘Celeste’ — with a little castile soap to lubricate the stainless steel shot. I leave the machine on for several hours with a batch of jewellery in it, using electricity powered by 100% renewable energy.

The polishing tumbler works great for pieces like the braided grass ring with texture, but for pieces with a curved or flat surface area that need a mirror polish, I take them though a hand polishing process instead.

Once out of the polishing tumbler I give the ring a gentle wash with warm water and polish with a soft cloth before tucking her into her hemp pocket to make her journey safely to her forever home.

I hope you enjoyed joining the braided grass ring’s journey.

If there’s anything you’d like me to explore as part of Behind the altar, let me know in the comments.

L x

Behind the altar | Vol. 1 Branding

For the first volume of my new project ‘Behind the altar’ I walk through the journey I’ve taken with my branding so far

WELCOME

to

BEHIND THE ALTAR

On the bench — wax work

Welcome to the first volume of my new project, Behind the Altar —

A place to take you behind the altar to explore what really goes on behind the scenes — on the bench, on set, and anything else you’re curious to know.

Expect unpolished content, grubby fingers and a proper peek at what goes into making Ara a responsible brand.

VOL. 1 — BRANDING

For Volume 1, I thought it fitting to return to the beginning of my journey and explore the branding that captures the foundation of Ara in graphic form.

One of the things I love most about managing my own small business is all of the creative aspects I get to play with, a favourite being graphic design.

I am no expert when it comes to graphic design with no training or experience but feeling so close to the brand and it’s portrayal —and launching my brand without any financial support— it was something I was really keen to have a stab at myself.

I thought I’d walk you through the journey I’ve taken with Ara’s branding so far — from where it began to where it is now. You will likely recognise this pool of graphics from across my website, packaging, accompanying cards and stamps, and across platforms — in the content I share on Instagram and in Letters of Ara.

Adding graphic elements to my sample sale imagery

THE SOFTWARE

—

I use Adobe Illustrator for all of my graphic design. Anything from branding to Instagram posts and the monthly graphic illustrations I used to create for Letters of Ara see them here.

This programme gives me scope to create something completely unique to Ara. I pay a monthly subscription which gives me access to other programmes like Photoshop and Lightroom which also enable me to edit all of Ara’s images myself.

Something I’ve found tricky with graphic design is the limitless possibilities it permits. I’m admittedly not the most decisive person and with so many potential design directions to explore, I find it really tempting to explore different avenues and hard to commit to one in particular.

So my main approach is to play. I try and work fairly intuitively and that way I can learn the skills needed for a particular task as I go, rather than feeling overwhelmed to learn everything.

The original logo

WHERE IT BEGAN

—

THE LOGO

In 2017 I sat down with a blank illustrator document and literally wrote the words Ara the altar in about 40 different (but very similar) fonts. I wanted to find just the right fit at this stage to create a logo I could commit to and something I knew I’d love for years to come.

From the offset I had some little hand sketched symbols in mind but when attempting to incorporate them into my logo it just felt too busy. No matter what I tried, I kept coming back to a simple line to separate Ara and the altar. Ara translates from Latin as the altar so this added some distinction as well as visually translating the brand name. I decided to use the sketched element for the line to add a hand drawn aspect to the design.

As various apps and platforms require branding to fit within particular shapes and dimensions, I also needed to create a logo that would fit into a square or a circle. For this, playing around with the original logo layout led me to stack the words in a way that created more of an ‘altar’ structure.

The original square logo

Current branding — a graphic depiction of the brand

WHERE WE ARE NOW

—

In 2018 I introduced something more visual to depict a physical altar and the notion of an ‘offering’ upon it.

The way I approached the design was to think around the the notion of Ara as an altar upon which to offer objects, with a nod to Ara’s core influence — the ancient world’s relationship with astronomy and nature.

This developed into the idea of creating a logo with an altar that could be used alone as a simple graphic but one that could also be added to with interchangeable symbols representing different areas of influence upon the altar.

This finally gave me an excuse to incorporate some of the little symbols I’d developed the first time around — and to play with colour.

Early work in progress developing the altar logo

THE ALTAR

—

I wanted to create an altar that could stand alone as a graphic without the addition of the symbols. Something simple that captured Ara and would be instantly recognisable.

When it comes to the ancient world I’m most closely drawn to Ancient Rome. After researching ancient altars and looking back through images I took when in Rome many moons ago, I worked on and kept tweaking a simple line drawing for the altar, adding the word ‘Ara’ as if it had been carved in stone.

At this point I also played with a dome shaped altar but although I liked it aesthetically it arguably looks more like a gravestone so I stuck with a more literal interpretation of an Ancient Roman altar.

You can see here I also had a brief play with a truncated version of my logo in letter form — the acronym ATA. I had completely forgotten about this and actually really like the shape and symmetry so may return to this at some point. Let me know what you think of ATA.

Early work in progress developing the symbols

THE SYMBOLS

—

When first exploring symbols I had various different elements that I wanted to capture.

Initially for this, the idea was to create a pool of symbols which I could alternate upon the altar.

The more I played with the symbols the more I became drawn to a simpler approach - capturing only two symbols to depict astronomy and nature as the two key influences.

I developed the ‘flora’ symbol to represent nature; a symbol often used in Ancient Rome. To capture astronomy, I combined Luna and Sol to sit above and shine down on the flora offering.

COLOUR

—

As black felt too flat, I use a deep but soft brown (like the earth) as the main colour for my logo.

With the introduction of the graphic depictions, I’ve found these colours have shifted over time, sometimes seasonally and otherwise depending on how I’m using the branding.

I currently have a pool of colours that I pull from but expect this will continue to evolve. Traditionally a brand will have a core set of colours which whilst I do have, I also like the flexibility of allowing these colours to ebb and flow.

I hope you enjoyed this little insight into the thought process behind Ara’s branding. I have a list of topics growing for subjects to explore as part of Behind the altar — if there’s anything you’re curious to know, just let me know.

L x

NATURAL DYEING WITH PINE NEEDLES

I share the process I used to naturally dye European hemp fabric with pine needles, for Ara’s accompanying bags

European hemp fabric hand dyed with pine needles

NATURAL DYE | A PROJECT

—

Last year I began a long overdue project to naturally dye the fabric used to make the bags which accompany Ara adornment.

I began my dyeing journey with avocado stones and skins - producing a dusty rose (if you’re new to avocado dyeing I wholeheartedly recommend Kathryn Davey’s ebook) and then onion skins - producing a rich ochre and a soft apricot - pictured below.

Ara adornment accompanying bags, naturally hand dyed with onion skins

PINE NEEDLES

—

It seemed fitting to begin this year by putting to use something I had in abundance - pine needles.

I couldn’t find much advice online about creating a dye bath with pine needles but I knew it could be done so went into it with an open mind and relatively low expectations.

I ended up so besotted with the soft mauve-clay colour produced by the pine needles that I dyed four pieces of my European hemp fabric with the same dye bath.

I am no expert in natural dyeing but if you’re interested in the ins and outs, I’ve shared my process below —

I | PREPARE THE FABRIC

The natural fibres of the hemp fabric I chose to work with needed to be scoured before dyeing to ensure the fabric would take the colour evenly. For this, I popped all of the fabric on a 40 degree wash with my usual fragrance free washing powder and a cup full of bicarbonate of soda - no fabric softener.

The second part of prepping the fabric was to soak it in water before it went into the dye bath. From previous dye projects I’ve gotten in the habit of soaking my fabric for about an hour before it was time to add it to the dye bath. This prevents the dye sitting in any creases once the fabric is added to the pot.

II | PREPARE THE DYE BATH

The general rule is to use 1 part dye to 2 parts water. If I’m honest I haven’t stuck to this religiously, I’ve enjoyed the freeing approach of working with what I have and I’ve still been completely mesmerised by the results.

This time, I collected a box full of pine needles (approx 30cm x 20cm) which went into a 20 litre aluminium pot. I usually dye one piece of fabric (1m x 1.5m) at a time - when it comes to the size of the pot and the amount of liquid you use, the main thing is that there’s enough liquid to cover the fabric, with a little room for it to move freely.

I filled the pot with cool water and added the pine needles, popped the lid on and brought the pot to a simmer, but not a boil. From this point I turned the heat down a little and left it on the heat for as long as felt right. I just played this bit by ear. Once I was happy with the direction it was going in I turned the heat off, leaving the pan on the hob.

III | STRAIN THE DYE BATH

Once I was happy that the water had taken the right intensity of colour, the next step was to remove the pine needles. I didn’t sieve the pine needles as I didn’t have a spare pot big enough to pour the liquid into. So I just fished them out with a fine mesh sieve.

Generally, if you want to achieve a really even colour the advice is to strain the fabric through muslin or a sieve. Any little bits left could result in deeper patches of dye on your fabric.

IV | ADD THE MATERIAL

After adding the material to the pot, I spent a bit of time gently working out any air bubbles in the fabric with a wooden spoon, making sure all of the fabric was submerged.

I brought the pot to a gentle heat again for an hour or so and to avoid the dye sitting in the creases, I’d return to the pot every so often to stir and unsettle the fabric.

And then it was just a game of patience. The longer you leave it, the stronger the colour will be (where there is still colour to give). It’s also worth bearing in mind that when the fabric is wet it’ll looks darker than it will once dry.

V | WASH THE FABRIC

When I was happy with the colour of the fabric I wrung out the fabric and popped it back in the washing machine with my fragrance free washing powder again and no fabric softener, to wash and rinse out the dye. This is always the scary part incase the dye all runs out but I was even happier with the final result than I imagined I would be.

Finally I hung it up to dry; the advice for naturally dyed fabrics is to avoid direct sunlight to prevent the colour from fading.

VI | REUSE OR REPURPOSE THE DYE BATH

One thing I noticed with the pine needle dye bath is that the intensity of the colour actually got stronger over time. I was so pleased with the results that I used the dye bath over and over again.

Once I was finished with the dye, I added it to our compost, to be returned to the earth.

~

If you decide to give this a try too let me know how you get on - I’d love to see your results.

The fabric I dyed will give me enough for a few batches of accompanying bags, as well as something else I have planned for this dusky coloured hemp.

I can’t wait to introduce you when the time comes.

L x

Handmade recycled silver & gold findings

Ara’s approach to offering fully recycled adornment, with transparency

𝐷 𝐼 𝑌

Since the conception of Ara, if I couldn’t source something I needed in recycled silver or gold, I either learnt to make it myself or simply didn’t use it.

This ensures Ara’s values are not compromised by offering something made from virgin metal for the sake of convenience.

Typically in the industry, ‘handmade’ silver and gold jewellery still uses findings (jump rings, earring posts, earring scrolls etc.) that are mass produced, usually using virgin metal, without any information concerning origin or ethical production practices. So often, even when jewellery is advertised as recycled silver, the main piece (eg a pendant or hoop) may have been made using recycled silver, but the accompanying findings will not have been. Often this use of virgin, untraceable metal is omitted from claims of a recycled product, which can make it hard for consumers to make truly informed purchasing decisions.

In my search to find recycled findings, although I was able to source recycled silver earring scrolls, I could not source recycled silver earring posts or jump rings, so I didn’t start offering earrings or pendants until I learnt to make these findings myself. Similarly, until I was able to source recycled silver/gold chain, I offered only rings. More recently, my supplier became unable to source the recycled earring scrolls, so I gave myself time to figure out how to make them myself.

I still have a few pairs of the existing recycled silver scrolls but have begun making my own recycled silver scrolls (pictured) for the molten earrings. As my joints are hyper-mobile, more intricate work like this can be a little tricky for me. In the future I’m looking forward to exploring other ways of working but -for now- I’m over the moon to offer this adornment, made completely by my own hand, responsibly and with transparency.

𝑅 𝐸 𝑃 𝐴 𝐼 𝑅

I was recently approached by a lovely Ara customer to repair a weighty brass plated necklace with a snapped clasp. Unable to source recycled brass wire, I made a replacement clasp from recycled solid gold, adding strength and longevity to the necklace. I really enjoyed making this and I’m pleased with how it came out - something quite simple but beautiful,

When you purchase jewellery, solid precious metal is the circular choice. Not only will the adornment be stronger to stand the test of time, the solid gold or silver will not wear away to reveal another metal underneath. And, at the end of its journey with you, the adornment can be passed onto another or even melted down and turned into something new for its next chapter.

Lauren

☾

Ara's accompanying cards: a responsible journey

An insight into my journey of designing and making Ara’s considered accompanying cards

Ara’s new information booklets, printed locally with vegetable ink on FSC accredited paper

The brief

I see part of my role with Ara as being vocal about the considerations I make, to help raise awareness and normalise a responsible approach to production and consumption. So, in addition to my existing comment cards, I wanted to introduce something that would share with the recipient the thought and care that goes into the entire journey of every Ara piece - something that would also serve a purpose for those who receive a piece of Ara adornment as a gift from another - but it was important to me that this should not be at the expense of producing something excessive or wasteful.

When it comes to anything that accompanies Ara adornment, striking the balance between creating something purposeful and low impact can take me on quite a journey. Whilst many companies now offer ‘eco-friendly’ solutions, it’s really tricky to find business cards, postcards or stickers that truly feel like the right fit for Ara. For example, smaller batches (often required by small businesses) of cards are often printed digitally, using toner rather than vegetable ink (even ‘eco friendly’ toners are still made using plastic polymers within the ink) with limited options for recycled paper, often white thin and bleached bright white. The paper used to make the stickers may be recycled or biodegradable, but the glue may not be etc. - there always seems to be a compromise. As nothing on offer felt quite right, this led me to have Ara’s existing comment and necklace/earring cards letterpressed here in the UK without ink on recycled stock, by a small independent company, Artcadia, who also work to minimise waste throughout their own production process.

As a consumer myself, I have in the past received many accompanying letters, cards, envelopes etc. from brands, and whilst they added to the initial experience when opening the product, many of them served little purpose thereafter. I was very mindful that anything I created to accompany Ara pieces should be something the recipient would want to keep, would have purpose, that could be easily recycled, and ultimately -at the end of its journey- would safely and easily go back into the earth.

Ara’s approach

After a lot of research, it was evident that what was on offer from larger printing companies was not the right fit for Ara. After some further research into the least impactful route, I decided to go with lithography printing, whereby the image is printed using a lithographic limestone or metal plate. The image is printed four times (CMYK) and -most importantly- the printing can be done with vegetable inks. Typically, this process is adopted for large scale runs as -due to the set up- it is not cost effective to litho print in small batches. Knowing this was the route I wanted to take, I did some initial research to determine roughly how much this option would cost. Rather than choose a cheaper option that did not site quite right with Ara’s values, I chose to wait until I was in a financial position to pursue this as an option. This is a prime example of where making considered decisions really does slow down the rate at which I am able to introduce new offerings. Naturally - more considered options are more heavily reliant on not just time, but also money. I knew that I eventually also wanted to offer some new postcards as well. By waiting until I was in a position to have them both printed, I was able to put the job through together.

Without question I wanted the the cards to be printed in the UK, but I also wanted to produce them as locally as possible, not only to keep CO2 footprint to a minimum, but also to support the local economy and a fellow independent business. Upon consulting my local printer, Heaton Press, I explained to them the approach I was trying to take -with minimal environmental impact- and, although comparatively to their regular litho jobs this would be a small job for them, they agreed to support my project.

Ara’s new postcards, printed on carbon neutral paper made in the Lake District

The design

I decided to produce not just another card, but a neat little four page booklet, something that could be kept and revisited at a later date, to give the recipient a sense of the thought that had gone into the journey of their chosen piece of adornment, allowing them to get to know Ara a little better along the way. I also chose to include some practical information about how to operate Ara’s unique bags.

Making the cards A7 would keep materials to a minimum and, thinking more practically, A7 would also fit neatly with Ara’s existing comment cards for packaging. To keep ink to a minimum, and make the most of my chosen paper, I kept the background transparent, choosing to print the text, logo and illustration using one colour.

I designed each of the four pages using Adobe Illustrator. Graphic design is one aspect of managing a small business that I really love but admittedly not something I know I whole lot about. I’ve just figured out what I’ve needed to know as I go. I had all the fun of the fair ensuring my images were exported correctly in CMYK, rather than RGB which I usually use for anything digital.

The finished booklet design

The postcard proof from the printers

The paper

Aware that I was after something suitable not just for this particular job, but also to suit Ara’s values, my printer offered me the flexibility to source the paper myself. This was great as it meant I could liaise directly with the paper supplier, and ask any questions I had about the production etc. to determine what would be most appropriate. In the end, I chose two papers to complement the off-white recycled card stock I was already using for Ara’s comment cards - both FSC accredited papers made locally in the LakeDistrict; a soft blush tone for the little booklets and an off white, carbon neutral paper for the postcards. Both of the papers were uncoated to ensure that they would biodegrade and were not treated unnecessarily.

At my request the printers also saved all of the off-cuts of paper for me, so that I could put them to use for another project, rather than needlessly letting them go to waste.

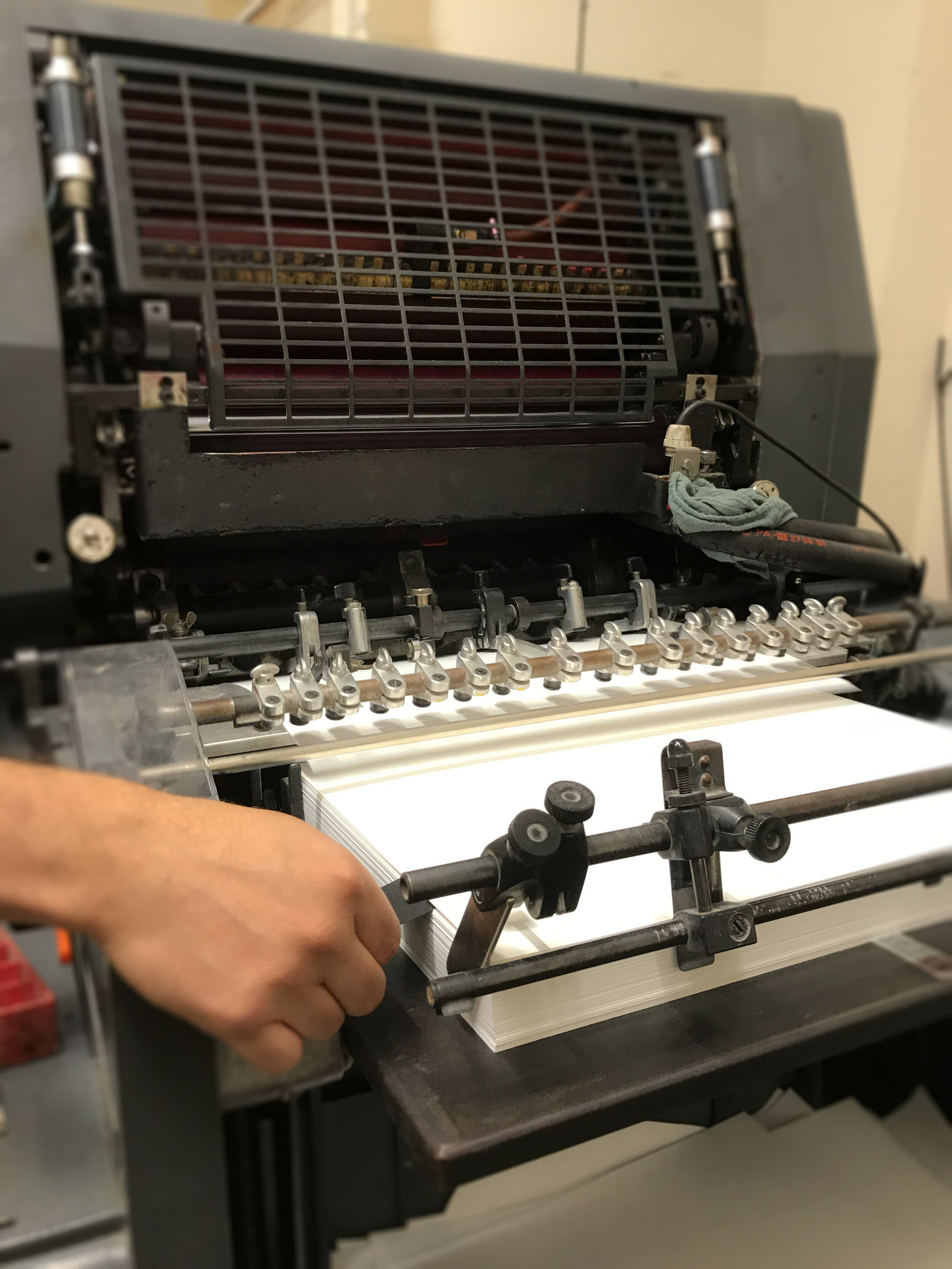

Loading up the postcard paper

Paper off-cuts for me to take home

The printing

Once I had supplied the final artwork for the booklet and postcard to the printers, I popped in to drop of my paper and to have a look at a printed version of the proofs. As I’d chosen to work with uncoated paper, the printers advised me that it would be tricky to get a sharp image for the full colour postcards. Uncoated paper is prone to absorbing more of the ink, resulting in a less predictable end result, and why a coated paper is the more common choice. They showed me a version of my postcard printed on coated paper - the level of detail was incredible by comparison but I knew this was not worth compromising Ara’s values for the sake of a sharper image.

Due to the paper’s absorbency and warmer than white colour, the printers explained that it would also be tricky to get an accurate colour match from the proof. The beauty of working with a local business meant that they were in a position to invite me to pop back when they were putting my job on the press, so that I could see how it would look and check I was happy before printing. When I popped in on the day, the staff were able to tweak the input of each colour (CMYK) to adjust the overall finish. Working with a limited supply of my paper, this wasn’t the easiest of tasks but they did the best that they could do for me within the time available and I really appreciated their efforts to accommodate my approach.

Images taken during my visits to Heaton Press

As the uncoated paper and vegetable ink can take a while to dry, I picked up my jobs and scrap paper the following week and was delighted to find them packaged without any plastic.

I’m so pleased with the finished products. It was definitely worth the time and effort to be able to offer something that feels like a true reflection of the brand.

I hope that you enjoyed this peek behind the scenes and that you love receiving Ara’s new postcards and info booklets with your adornment. I’m always looking to improve so would love to hear your feedback.

Lauren

☾

A Lammas Gathering | Ara’s first pop up

Behind the scenes at Ara’s first pop up with a focus on sustainability, slow-making and pleasure

As I make to order and primarily operate as an online business, I hadn’t intended to venture into having my own physical presence for quite some time. Whilst Ara pieces have appeared at other brands’ pop ups and in-store, I hadn’t created my own display before. I knew that prepping a set up for Ara would be a pretty hefty undertaking, particularly mindful that it would be important to me to ensure the brand’s values were reflected in the right way, and with minimal environmental impact along the way.

BUT when the lovely Blue of Dohm Shop invited me to join her first collaborative pop up ‘A Lammas Gathering’, in her home town of Nottingham, I knew without doubt it would be the perfect setting for Ara, and it felt like the right time to dip my toe into this real life interaction malarkey.

A Lammas Gathering brought together a careful selection of women owned brands to hold a relaxed event with a focus on sustainability, self-care and pleasure, with donations accepted upon entry for Nottingham Women’s Centre.

The prep

Although I had a limited timeframe within which to prepare, I design for longevity and wanted to extend the same approach to the planning of my set up. It was important to me to create a display that I would be able to use again and again, that would easily adapt to different spaces. So I did a little research and gave myself a brief, to create a display that:

i) was first and foremost low impact

ii) was reflective of the brand and its values

iii) was practical for its purpose (and hopefully inviting)

The backdrop

To lay the table, utilising what I already had, I used the same linen and GOTS certified organic cotton that Ara’s low waste bags are made from. This provided a natural base from which to build the rest of my display.

Jewellery display

I wanted to create a few main areas for my pieces to sit. On this occasion I only planned to display two styles but to ensure flexibility for the future I designed and made a series of blocks using FSC wood that could be used singularly, or stacked to create variation. For Lammas, I created a little set of ‘stairs’ on which to place or drape the Molten samples (to the right), and used a single large block to display the Phase adornment (to the left).

To add a little distinction between the offerings, I painted the boards different colours - the stairs a pale grey, and the remaining blocks a warmer blush colour, using water based paint, made in the UK.

Playing around with the set up at home

Coat #1 of 2

A few practical things

I had a good think about what else might be helpful to have close by on the day. I packed a ring sizer (which came in really useful as I ended up taking three rings back to the workshop to resize), a sign-up board for anyone wishing to join the Letters of Ara newsletter, and small mallet and ring mandrel to make rings a little bigger in case the need arose.

Newsletter sign up sheets, a few resizing tools & my trusty fountain pen

Figuring out a lovely customer’s ring size to resize this rose gold Full Moon Ring

Artemis

As I decided to take a few gold pieces with me, I wanted something a little special on which to display one of the full moon pendants. Rather than buying something ‘new’ I was over the moon to find a pre-loved bust of Artemis (complete with a chip at the back) who I knew would make the perfect accompaniment. Interesting fact - when exploring brand names many moons ago, I toyed with the idea of ‘Artemis the Hunter’, with the notion of Artemis, goddess of the hunt, sourcing beautiful objects for the offering.

The altar

I knew I would need to have some kind of branding on the stall and, without question, it had to be an altar. David helped me to make one -again from FSC wood- using dimensions that follow the golden ratio (1:1.6...) which goes back to Euclid and was employed by the Roman architect Vitruvius. It was since used in Georgian and Neo Classical building, and also portrayed in Art (e.g. by Dali). So I knew my little altar would be in good company with this approach.

To incorporate my branding into the altar, we created a cloth overlay from European grown hemp, and the folks at one69a in Manchester screen printed my logo with soil association approved ink. To finish, I added a little offering of found natural objects to the top of the altar.

A little detail

I also took along the amphora that features in some Ara photography, which I found via EESOME and some postcards. To communicate Ara’s offering, prices, and an overview of the brand, I also made some little display cards using FSC accredited paper.

The offering

Mindful of the time that I had to prepare for Lammas alongside other projects -and very conscious to keep to my slow making approach- I made a small offering of recycled silver & gold Phase pieces and dusted off a pile of molten samples that, about 18 months earlier, I had created as part of the development of a collection that ended up taking a slightly different turn (keep your eyes peeled for that one).

The molten samples were all completely one of a kind, made using recycled silver scrap from my workbench, carefully positioned and heated until melting and solidifying into a molten form. They were really well received so -after some feedback- I might begin offering some molten pieces online.

The community

The community was so welcoming, upon arrival the fellow women business owners were so lovely, we passed some Incasua incense around each of our spaces and I felt right at home in-between my lovely neighbours.

The same community feel was consistent throughout all of the folk visiting the pop up. It was such a pleasure to meet lots of like minded people, some of whom already knew about Ara which really made my day; it was so lovely to chat with customers in real life. I get so used to working in my own bubble so it was really encouraging to know there’s a place for Ara at this kind of event.

Keeping low impact

As usual, I took my water bottle and insulated pint pot with me to top up on the tea (it also helped that we were situated above a pub so were able to stay ‘hydrated’).

As I wasn’t sure what the food situation would be, I made a vegan grilled cheese sandwich to take with me which ensured I wasn’t creating any rubbish. In the end I was glad I’d done a little prep as once things were underway I didn’t want to leave my stall and miss out on chatting with the lovely Nottingham folk!

Logistics wise, I packaged all of my display things in some wooden crates, using blankets to protect the breakables.

The day absolutely flew by and the whole experience was such a pleasure. After a long day with a trip back to Manchester ahead of me, I grabbed some dinner with one of my lovely neighbours - the perfect end to the day.

I’m so grateful to Blue for inviting me to play, to the fellow women brands who made me feel so welcome, and to everyone who chatted with me about Ara, joined the newsletter or took a piece of adornment home with them.

Thanks so much for having me, Nottingham.

Lauren

☾

Purposeful Packaging | Designed & Made In House

An introduction to Ara’s new packaging, designed & made in-house with minimal waste, using fabric woven in Lancashire.

For the first chapter of Ara the altar’s journey, the GOTS certified, organic cotton drawstring bags -which I had made specially in a carbon neutral factory as part of an ethical supply chain- have served me so well. For some time, however, in preparation for coming to the end of my supply, I have been looking for a way to further minimise Ara’s carbon footprint by bringing the production of my presentation packaging in house, in line with the slow approach I adopt in my jewellery design and production. The brief I gave myself was threefold:

1) Purposeful

To me, it feels counter intuitive to waste energy and resources creating packaging that would provide little value, use or longevity for my customers. Instead, I wanted to create a product that would be long-lasting and functional, in which to keep Ara pieces safe.

2) Low Impact

With respect for people and the planet integral to every aspect of the brand, it was of paramount importance to source a traceable, locally and ethically produced fabric, created from natural, sustainable materials. Furthermore, it was important to me that the design and methods used to produce the product itself would ensure minimal environmental impact and minimise waste, with a zero waste goal.

3) Reflective of the brand

Whilst first and foremost the packaging would have an intended purpose, I also wanted it to be something for Ara customers to treasure - not something mass produced but a slow-made keepsake to accompany their chosen piece.

After months of research, design and finding sewing pins everywhere, I am so pleased to share with you my new, slow-made, purposeful packaging that has been thoughtfully designed and created in-house; designed and developed by me and my partner, David, who has learnt to sew on a 1921 Singer to make these little pouches that will accompany every piece of Ara the altar adornment.

The Fabric

I began my search for a fabric that had been created with utmost respect for the earth. After some initial research I knew I wanted to work with hemp or linen, given their very little reliance on water or pesticides. It transpired that most of the hemp suitable for this project was made in China (which did not meet the requirements of my brief when concerning Ara’s carbon footprint). Whilst I did manage to source more locally made European hemp the fabric available to me at the time did not possess the qualities suitable for this particular project. I am, however, really keen to support the use of this fabric so keep an eye out for an exploration into hemp later down the line. In continuing my search for the perfect, earth-kind linen, I was delighted to find a very special fabric with UK based company, Bysshe, who source fully traceable, European yarns, and weave them into beautiful fabric, here in the UK. This small, independent company ensures “the highest quality at the lowest environmental cost, developing fabrics for a sustainable future”.

I fell for a beautifully tactile, twill cloth, woven on a Jacquard loom in Lancashire. The fabric is constructed of linen weft yarn, made from certified European Flax in France by a Masters of Linen certified company. The linen weft yarn is woven across GOTS (Global Organic Textile Standard) certified organic cotton warp yarns. The fabric was then finished in a specialist finishing mill up the road in Yorkshire. Finished without bleach treatment, this fabric celebrates the natural hues of the flax and organic cotton. On one side, the natural linen is more prominent -slightly flecked throughout, in warm, natural, earthy tones- and on the other side, the organic cotton twill is more prominent, appearing lighter due to its natural hue, and incredibly soft to the touch.

The Design

When it came to the design, our aim was to develop a pattern that would make the most effective use of the fabric with the least waste. We also had to consider the product’s intended purpose (to keep its cargo safe), and to ensure that the design would suit the thickness and properties of the fabric. Consequently, we chose to design a little pouch that would not rely on a drawstring closure (again to further minimise waste) and we developed a design based on a simple, repeatable rectangle to ensure minimal, if any, fabric waste.

Our unique design utilises a sewn down, fold-over top to keep belongings neatly tucked away inside. At first glance, it might not seem obvious how to easily open the bag. By folding the top flap inside-out, the full width of the opening is revealed, and the treasure can easily be tucked in or taken out.

The Production

It was important that the production of the bags reflected the production of the pieces: slow. For this project, my partner, David, learnt to sew on a very special Singer sewing machine from 1921, spotted and purchased in a charity shop by my grandad, and given to my mum many years ago. By managing the production of the bags in house, using GOTS certified natural organic cotton thread, and traditional production methods powered by 100% renewable energy, Ara the altar can continue to tread even more lightly whilst creating our earth-aware offerings.

I think these bags are really special and truly reflect Ara’s ethos. I am so pleased that one of these little pouches will accompany every piece of Ara the altar adornment.

Lauren

☾